Originally post by Doug Stovall, Chief Revenue Officer at Ossia on Sensors|Online

For decades, technologists have envisioned smart factories, power plants, and warehouses that run autonomously. Tended by human beings, robots with advanced artificial intelligence (AI) and legions of sensors could produce every physical good we need at lower costs than societies have ever known. Manufacturing could return to the U.S. and Europe, closer to the primary consumers.

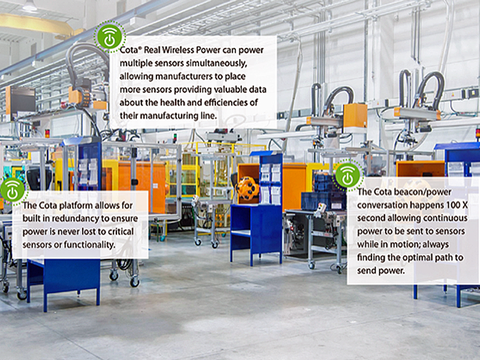

These visionaries missed a major blind spot. How do you power this Industrial Internet of Things (IIoT)? Not without wireless power. By “wireless power,” I mean systems that resemble Wi-Fi. They transmit data to devices in motion, within a certain radius, without line-of-sight. They require no pads or cables to circulate power. Wireless power can sustain sensors, small CPUs, and other light electronics used in manufacturing.

Rather than view wireless power as a novelty, we need to view wires and batteries as constraints on how we approach design in industrial systems, healthcare, cities, consumer products, office buildings, and dozens of other spaces. Today, wires and oversized batteries dictate what we can and cannot do. IIoT is supposed to create $3.7 trillion worth of value in factories, McKinsey estimates, but that’s a pipe dream without wireless power. To illustrate this point, let’s explore three reasons why conventional power hamstrings industrial innovation.

1. Cost

The advisory firm Lux Research predicts that the world will deploy 1 trillion sensors by 2020. It’s a staggering number. If factories accounted for just five percent of the sensors, we’re talking about 50 billion sensors. The cost would be prohibitive without wireless power.

Today, factories require extremely expensive wiring and battery systems to make even simple automations feasible. Industrial-grade sensors cost roughly $50 each and are becoming more affordable, but the wiring job can cost $1,000 per sensor. In many cases, it’s more efficient to pay developing-world wages than to introduce automation.

Conservatively, let’s say one wireless power transmitter has the range to sustain ten sensors, then you’re looking at $1,000 per ten sensors versus one $1,000 for each. That radically change the economics of automating a factory.

2. Downtime Prevention

IIoT depends heavily on sensors, without which robots and automated assembly lines cannot make goods. The sensors are a potential fail point. Plants do back up critical safety systems with generators, but most factories can’t back up tens of thousands of sensors. Wireless power addresses that shortcoming. If one wire or battery fails in an automated factory, an entire line shuts down. By one estimate, downtime in an automobile factory costs an average of $22,000 per minute.

Wireless power can prevent that scenario. Picture a factory in which each 30 by 30 ft. has a primary wireless transmitter connected to the grid. It powers sensors and other low-power devices that contain receivers. In the same space, there’s a backup wireless power transmitter connected to a generator. If the primary transmitter fails, the backup kicks in, and $22,000 per minute of downtime is averted. Put simply, wireless power addresses the risks of downtime in automated factories by providing redundancy.

3. Edge Computing

The power dilemma intensifies as we ask our devices to perform real-time actions. Consider that when we rely on cloud infrastructure, we don’t do it with applications that can put human lives at stake. We know too well that internet connections can fail. Thus, driverless cars carry the AI on board rather than depend on cell connections.

The same issues of safety and reliability arise in factories. Gartner estimates that by 2022, 50 percent of enterprise-generated data will be processed in or near devices rather than in the cloud. ‘Edge computing,’ as this is known, offers advantages for security, data costs, and most importantly, response times. No one would dare ride pilotless drones that needed cell towers to avoid a crash.

Factories have similar dependencies. Today, a loss of an internet connection could shut down an entire factory. As smart factories evolve, the intelligence must be onsite, nearer to the devices it controls. Dozens if not hundreds of processing units will, like sensors, need continuous sources of power.

What about batteries? Most of our devices don’t support powerful CPUs because the batteries take up too much space! That’s why your phone relies on Wi-Fi, cells, and the cloud, not an onboard computer, to perform its most advanced functions. Siri can’t be bothered to help you without an internet connection. Edge computing in automated factories will require wireless power to be reliable. The cloud is too risky.

A Manufacturing Renaissance

As U.S. and European manufacturers consider bringing production home to smart factories, they should plan for the inevitability of wireless power. The smart factories lauded by technologists need wireless power to contain sensor costs, prevent downtime, and support AI contained in edge computing units.

IIoT cannot reach its potential without wireless power. The new paradigms of manufacturing will require a new paradigm of electrification.

About the author

Doug Stovall is the Chief Revenue Officer at Ossia. He has been involved with leading edge technology companies his entire career. Previously, Doug was Chief Revenue Officer for Mobivity, managing sales, client services, and marketing. Prior to Mobivity, Doug held executive positions with Hipcricket, Inc., Acuity Mobile, Inc., TeleCommunications Systems, Inc., Aether Systems, Inc. and Xpedior, Inc.